Rely on SNK to streamline your aerospace machining process.

Aerospace demands the utmost in precision machining and maximum productivity, That’s why so many of the world’s leading aerospace manufacturers rely on SNK for their machining requirements.

From vertical machining centers for engine components to 5-axis horizontal machining centers for complex titanium and larger aluminum airframe components—SNK has the machine for your specific application. Our outstanding reputation for reliability means downtime is reduced resulting in lower production costs and greater return on investment.

Automotive

Rely on SNK to keep your business in the fast lane.

Automotive.

As critical tolerances are increasing and costs per part are decreasing, having a competitive edge is necessary. SNK machining centers, and services gives you that competitive edge by providing personalized attention to your rapidly changing production demands.

SNK machining centers deliver shorter part cycle times, with greater accuracy, stability, and repeatability. This means higher quality and productivity. This consistent quality is what makes our machines and systems critical to your manufacturing—and to shaping the future of the industry.

Heavy Industry

Rely on SNK to help build your business from the ground up.

Heavy Equipment.

Cost-effective, high volume machining of large parts for construction and mining equipment is critical. SNK machining centers have the precision, rigidity and reliability this market demands. Our horizontal machining centers, 5-axis profilers and boring mills are perfectly suited for the most stringent requirements.

Our application engineering staff can offer machining solutions to insure maximum productivity and profitability.

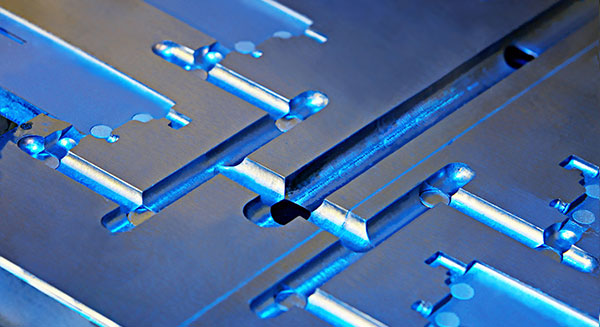

Die Mold

Rely on SNK to get that perfect finish.

A flawless finish is key in manufacturing dies and molds. SNK high-speed machining, and engineering services speed up the process while maintaining a high level of quality and increasing productivity. Eliminate multiple setups, manual handling, and the need to move parts from machine to machine. A flawless finish eliminates hand polishing.

Energy

Rely on SNK to power your business into the 21st century.

SNK has been supplying the energy industry with innovative machining solutions for over 75 years. The precision, reliability and capacity of our boring mills, horizontal and bridge type machining centers are ideally suited for the demands of the oil & gas industries.

Our dedication to manufacturing precise, stable and adaptable machining centers for medium-to-large workpieces makes them perfect for machining everything from turbine blades to gearbox housings for the solar and wind power industries. Fluid ends, cases & flanges and turbine components.

Transportation

Rely on SNK to keep your business moving.

Truck. Rail. Marine.

This industry may be diverse, but they all demand highly precise, stable and reliable machining centers for medium to large engine and chassis components. They also require versatility and in-field adaptability to assure minimal downtime and increase cost effectiveness.

SNK horizontal, 4 & 5-axis profilers and hybrid-type machining centers are ideally suited to keep your business moving forward. Chasis components, engine components, transmission components

General Machining

Rely on SNK to keep you on schedule.

SNK has machining solutions that can lower your costs and increase your competitive advantage. Steel, iron, aluminum, exotic alloys, short runs, complex features, SNK horizontal and vertical machining centers, deliver faster cut times, reduce non-cut times, improve part accuracies, yield better finishes and deliver superior performance.