High Performance Machines Tools

for Rail Industry Manufacturing

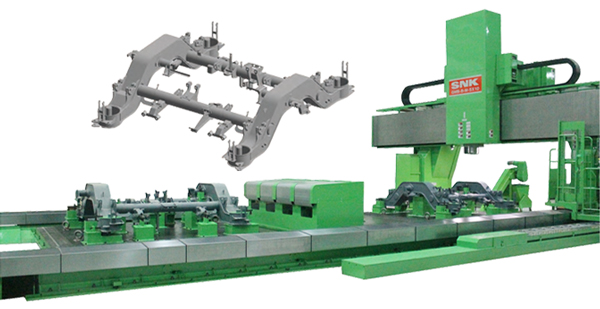

GMB

Gantry Mill

- The ultimate machine for Bogie Frame machining

- High-productivity Dual Work Zone design permits work set-up on one zone while machining on other zone

- AAC and ATC designed to service both work zones

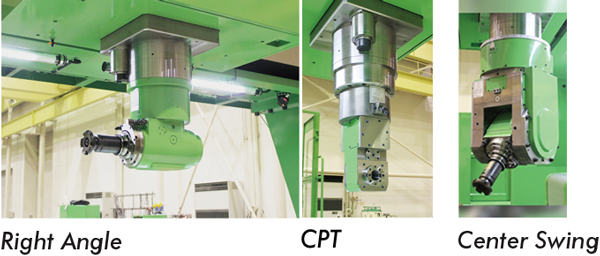

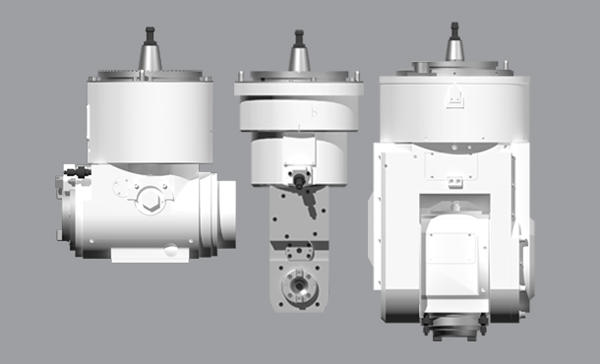

RB-5MII

5-Face Machining Center

- Extra-wide and extra-long table

- Attachments designed for machining tight workpiece areas and varied faces found on Bogie Frames

- Cost-effective choice for Bogie Frame machining

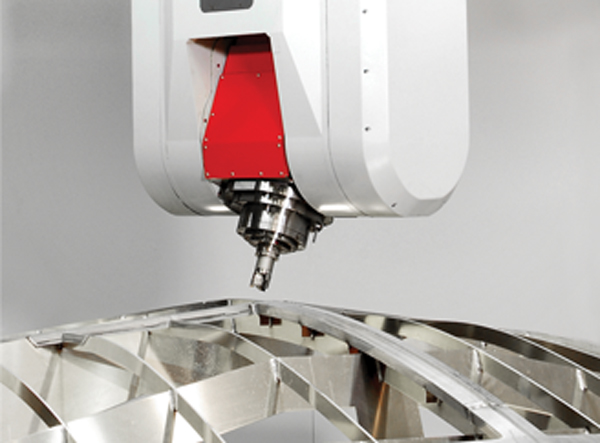

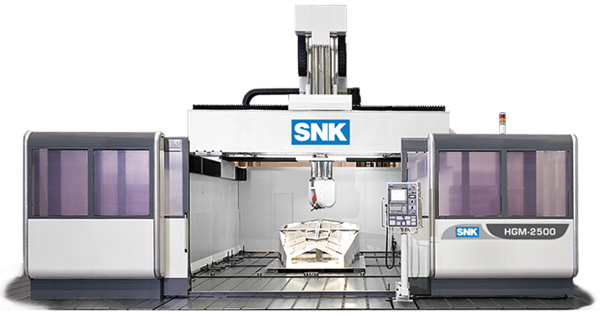

HGM Gantry Series

- Perfect for machining large multi-faceted parts

- Extraordinary 2,400 ipm feedrates

- Simultaneous 5-axis contouring capability

- High-power, high-speed spindle

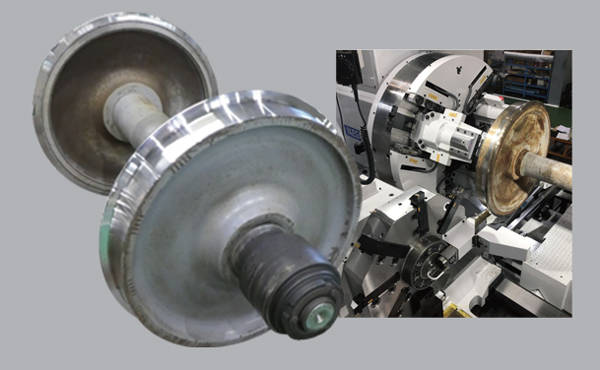

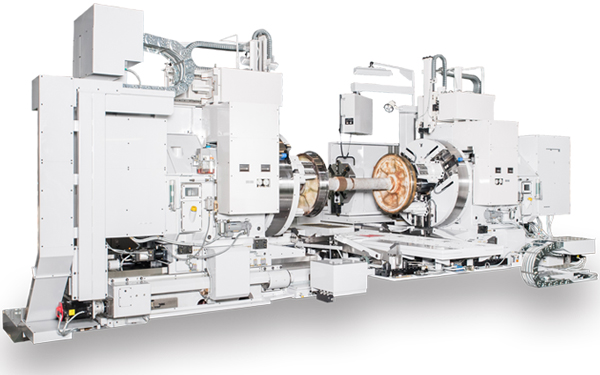

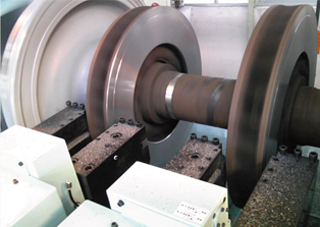

WL 1100

Wheel Thread Lathe

- Performs automatic machining in a single set-up

- Easy workpiece loading and unloading

- Simultaneous machine threading capability of both L/R wheels available

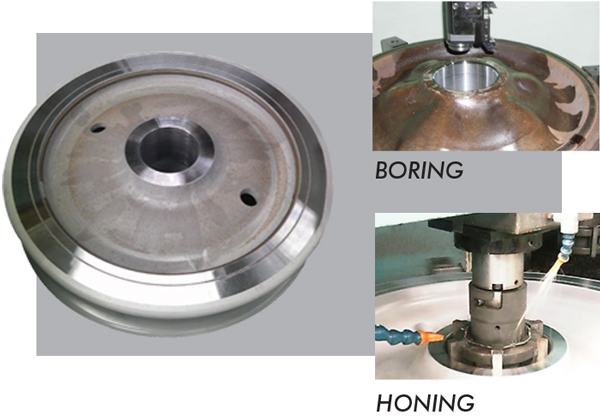

VT 1100

Vertical Lathe

- Performs Boring, Turning and Honing

- Ideal for turning of wheel faces and boss holes

- Small footprint

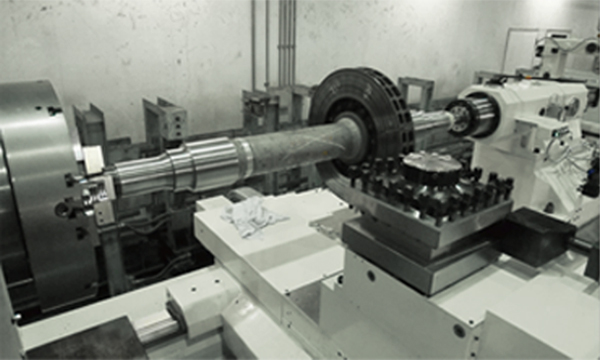

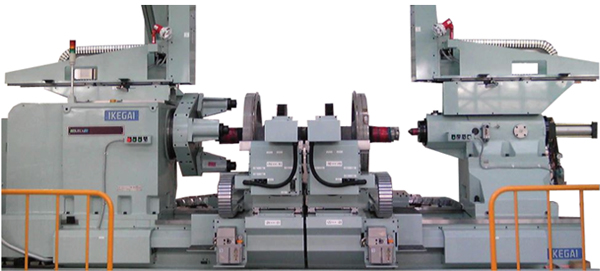

Wheel Center Lathe

- Saves time – Can process wheel assemblies without removal of Brake Disk, Gearbox and even 1 wheel

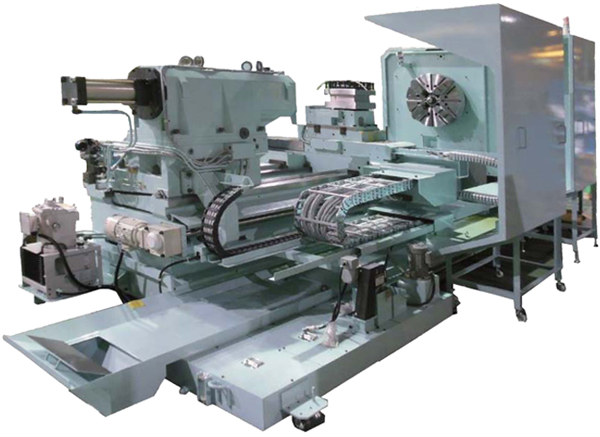

Brake Disk Lathe

- Simultaneous machining of left and right brake disk surfaces assures optimum parallelism

- Features automatic processing system including automatic measurement

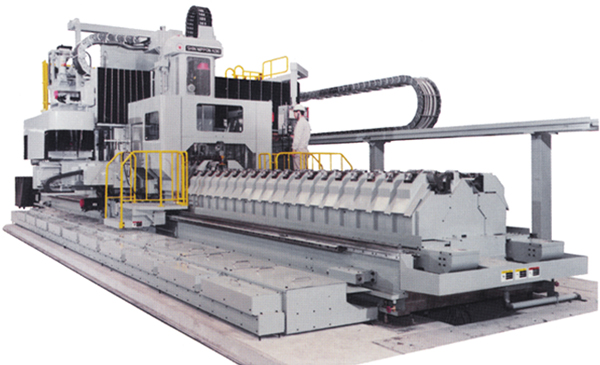

Automatic Rail Machining System

- Designed for continuous rail processing

- Dynamic Automatic Fixtures assure interference-free machine performance

- Rail stocker autoloader for trouble-free continuous operation

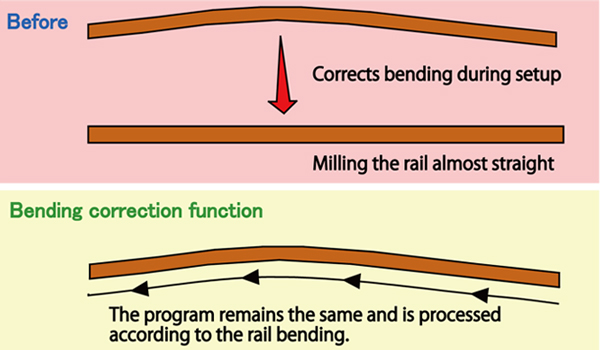

Rail Bend Correction System

- Extra long table accommodates long rail sections

- Special shaped tooling and robust fixturing permits machining with a high-torque spindle

- SNK “Bend Correction Function” automatically measures the amount of rail bend to milling required